Optimization of a decoking tool design was performed for a major pump manufacturer. The decoking tool is used to cut coke built-up on drum walls. This tool system consists of a high-energy multi-stage pump and a water jet nozzle that can spray 10 ft or more.

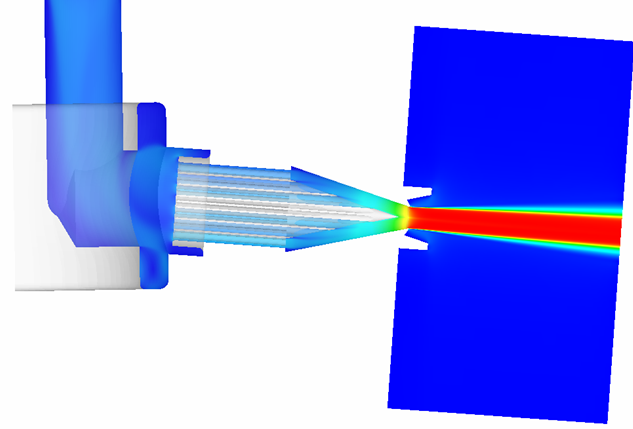

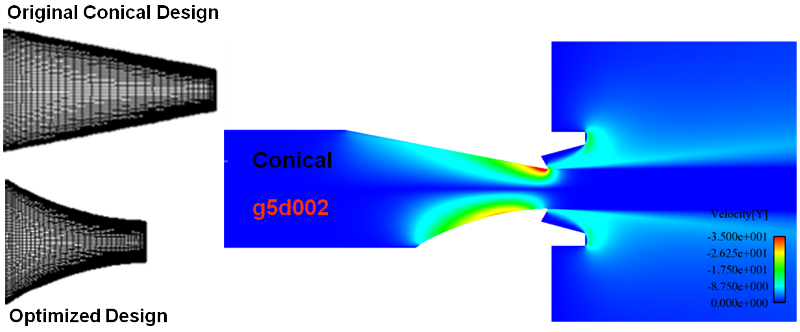

Cutting power of the jet is a function of jet integrity, which is determined by nozzle design. The goal of the project was to optimize the design of the water jet nozzle in order to obtain improved cutting performance while minimizing nozzle length.

The final optimized nozzle design was shown to minimize boundary layer thickness and radial velocity (vena contracta effect) while maintaining jet coherence. The final nozzle shape was also 50% shorter than baseline nozzle design. The optimized design was tested by manufacturer and introduced in product line.